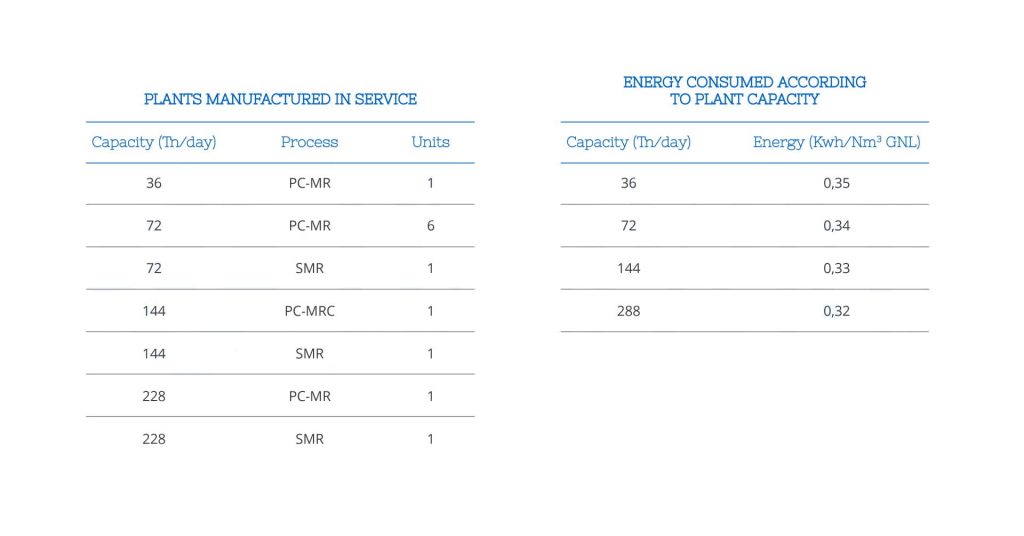

The typical sizes of the plants we design and build range from 15T/day to more than 300T/day of LNG production (18,000 to 375,000 Nm3/d). The system we usually use is the Single Mixed Refrigerant (SMR) system with its Mixed Refrigerant (MR) and Mixed Refrigerant Cycle (MRC) variants meaning that our plants ensure constant, reliable functioning at low costs and with simple operations.

AMG ICS has experience in both the SMR process and in the expanded N2 process. AMG ICS however recommends the use of the SMR process as this process is more efficient, offers greater productivity, energy consumption that is 22% lower than the expanded N2 process, and is a simpler process requiring less equipment, a compact modular design in addition to providing greater flexibility for the composition of feed in gas.

AMG ICS are able to provide support to our customers enabling them to become familiar with the process allowing them to operate the plant in a very short time.

Note:

Larger Liquefaction Plant (up to 3000T/day) can be designed and manufactured on a case by case basis, please get in touch with us directly with your requirements.